Air cooled water chiller industrial cooling plant

- Packaging:

- Wooden packing

- Productivity:

- 10000 set/ month

- Brand:

- TOYOCOOL

- Transportation:

- Ocean,Land

- Place of Origin:

- China

- Supply Ability:

- 10000 set/ month

- Certificate:

- ISO9001, CE

- HS Code:

- 8418699090

- Port:

- Shenzhen,Yantian,Hongkong

Basic Info

Model No.: TY-10A

Product Description

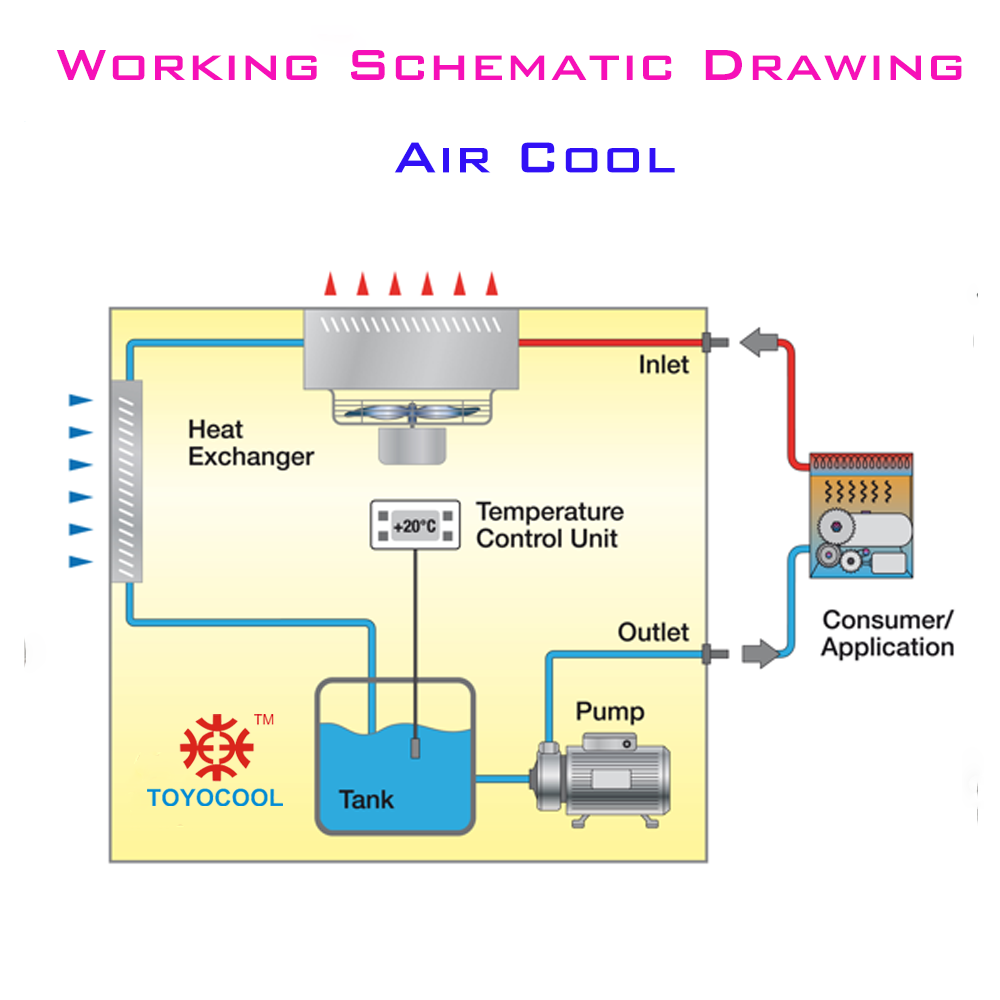

Air cooling chilling equipment,air cooling chiller machine,air chiller unit,air cooled chiller refrigeration,air cooled chiller refrigeration unit,air cooled chiller refrigeration machine

: Electroplating industry: control the electroplating temperature, increase the density and smoothness of the plated parts, shorten the electroplating cycle, improve production efficiency, and improve product quality.

Machinery industry: control the oil temperature of the oil pressure system, stabilize the oil temperature and oil pressure, prolong the use time of oil quality, improve the efficiency of mechanical lubrication, and reduce wear.

Air Cooled Chiller Refrigeration Equipment,Box-type Air Chiller Unit:

Condenser: In the cooling process, the condenser plays the role of outputting heat energy and allowing the refrigerant to condense. After the high-pressure superheated vapor discharged from the Refrigeration compressor enters the condenser, all the heat it absorbs during operation, including the heat absorbed from the evaporator and Refrigeration Compressor and in the pipeline, is transferred to the surrounding medium (water or Air) Take away; refrigerant high-pressure superheated vapor re-condenses into a liquid. (According to different cooling media and cooling methods, condensers can be divided into three categories: air-cooled condensers, air-cooled condensers, and evaporative condensers.)

Reservoir: The reservoir is installed after the condenser and is directly connected to the drain pipe of the condenser. The refrigerant liquid of the condenser should flow into the accumulator without obstruction, so that the cooling area of the condenser can be fully utilized. On the other hand, when the heat load of the evaporator changes, the required amount of refrigerant liquid also changes. At that time, the liquid reservoir functions as a regulator and stores refrigerant. For small chiller refrigeration system, often do not install a liquid reservoir, but use the condenser to adjust and store refrigerant.

Dry Filter: In the refrigeration cycle of the chiller, it is necessary to prevent moisture and dirt (oil, iron, copper) from entering. The source of moisture is mainly the trace water contained in the newly added refrigerant and lubricating oil, or due to Moisture caused by air entering when overhauling the system. If the water in the system is not removed, when the refrigerant passes through the throttle valve (thermal Expansion Valve or capillary), the water may freeze into ice due to the drop in pressure and temperature, blocking the channel and affecting the normal operation of the refrigeration device. Therefore, a drying filter must be installed in the chiller refrigeration system.

Evaporator: The evaporator is a heat exchange device that relies on the evaporation of refrigerant liquid (actually boiling) to absorb the heat of the cooled medium. Its function in the refrigeration system is to absorb heat (or output cooling capacity). In order to ensure that the evaporation process can be carried out stably and lastingly, the refrigeration compressor must be used to continuously evaporate the evaporated gas to maintain a certain evaporation pressure.

Thermal expansion valve: in the chiller refrigeration system, the thermal expansion valve is both a flow regulating valve and a throttle valve in the refrigeration equipment. It is installed between the drying filter and the evaporator in the refrigeration equipment. It is wrapped at the outlet of the evaporator. Its main function is to make the high-pressure and normal-temperature refrigerant liquid throttle and depressurize when it flows through the thermal expansion valve, and become a low-temperature and low-pressure refrigerant wet vapor (mostly liquid, small part of steam) enter the evaporator and vaporize in the evaporator It absorbs heat and achieves the purpose of cooling and cooling.

Refrigerant: Most industrial chillers used in modern industry use R22 or R12 as refrigerant. Refrigerant is the flowing working fluid in the refrigeration system. Its main function is to carry heat and realize heat absorption and heat release when the state changes.

Product Categories : Air Cooled Chiller > Box-type Air Cooled Chiller